asset management

Asset management is a logical approach to the governance and realization of value from tangible and intangible assets that an organization is responsible for over their entire lifecycle. Asset management software can be utilized to track asset inventories. The system also facilitates asset lifecycle management. The software can track assets at all periods right from acquisition to disposal.

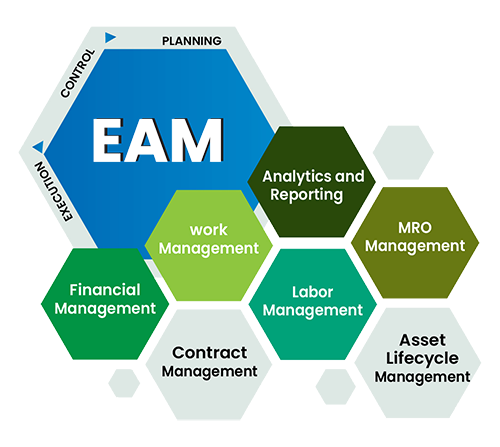

Enterprise asset management (EAM) is a mixture of software, systems and services used to sustain and manage operational assets and equipment. The goal is to enhance the condition and use of assets throughout their lifecycle, increase valuable uptime and decrease operational costs. Enterprise asset management encompasses asset maintenance, planning and scheduling, work management, supply chain management and environmental, health and safety programs.

EAM enables operating models to progress with organizational assets. EAM is a blend of software, systems and services utilized to sustain and manage operational assets and equipment. EAM solutions are aimed to improve the value and use of assets throughout their lifecycle, boost productivity and decrease operational costs.

Increase asset usage

Increase asset usage